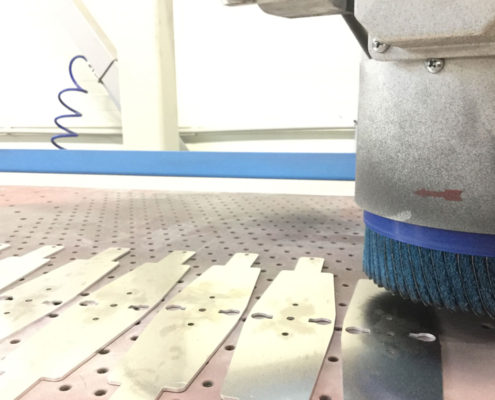

Fully automated sheet metal cutting-forming robot

The combination machine, AMADA C1 NT, offers press and laser technology with a small footprint. Using the laser unit eliminates the need for special tools, considerably reducing manufacturing costs, even for small lot sizes or one-piece flow production systems.

For integrated sorting of the components with a conveyer belt, and a fully automated material feeding system including waste material disposal.

Fronius CMT robotic welding cell

Fronius CMT robotic welding cell:Fronius ABB,CMT (Cold Metal Transfer) offers low dilution and a high deposition rate – compared to laser or TIG welding, it’s more efficient and economic.The CMT process was initially developed for welding thin sheets in the automotive industry, but is now finding new applications. It is ideal for steels, including stainless, as well as aluminium and galvanised sheets, and offers travel speeds of 400–500mm/min, compared with 100mm/min for TIG.

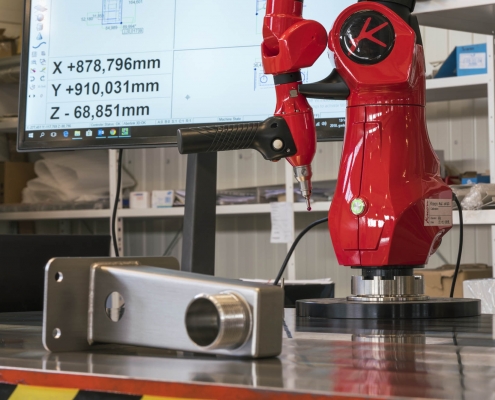

Fully automated sheet metal bending robot

The AMADA HG 1003 ARs bending automation solution reduces personnel requirements, increases production capacity, and ensures high-precision, error-free machining in absolutely unvarying quality.

With a robot, automatic tool changer (ATC) and gripper station, the AMADA HG-ARs press brake is ideal for the processing of small and mid-sized parts